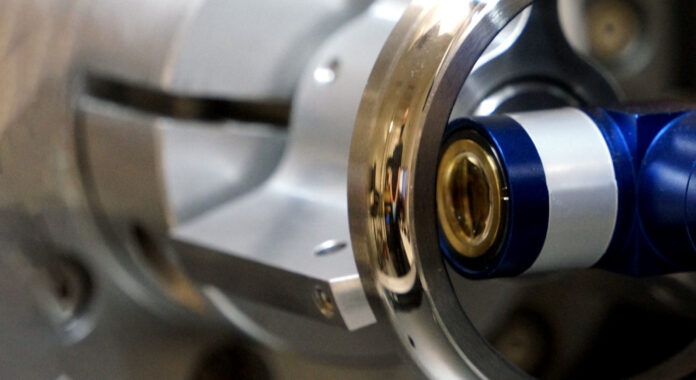

From the smallest of electronic components to the largest of industrial machines, flanged ball bearings are a cornerstone of precise motion control. As simple and ubiquitous as they may appear, these versatile mechanical devices have been used in countless applications for many decades.

From automotive engines to aerospace robotics, it is no exaggeration to say that without them our world would be very different. In this article, we explore some key aspects of flanged ball bearings – from their history and design principles right through to their current use in modern engineering.

Advantages of Using Flanged Ball Bearings

Flanged ball bearings are the cornerstone of precise motion control. They offer many advantages that make them ideal for a variety of applications, from light-duty to heavy-duty industrial settings.

To begin with, flanged ball bearings have superior radial and axial load ratings compared to other types of rolling contact bearings. This allows them to operate at high speeds without sacrificing performance or reliability.

Additionally, they can be used in nearly any environment as they resist corrosion and require minimal lubrication due to their low friction coefficient. Furthermore, since these bearings are self-aligning, installation is simple and fast – requiring no additional adjustment or maintenance after installation has been completed.

Overall, flanged ball bearings provide improved bearing life through better sealing options as well as lower noise levels than standard roller bearing designs; making them an excellent choice for precision motion control systems.

Identification and Selection Criteria for Flanged Ball Bearings

The selection and identification criteria for flanged ball bearings are a critical steps in the process of obtaining precise motion control. It is important to select the right type of bearing based on its intended purpose, as each has distinct advantages and disadvantages.

For example, radial bearings are more resistant to axial loads but may be less suitable for high-speed applications; whereas angular contact bearings can handle higher speeds, but require more space. Additionally, different types of materials have various levels of resistance to corrosion or temperature fluctuations which must also be taken into account when selecting flanged ball bearings.

Furthermore, specifications such as inner diameter size and outer diameter size should determine what type is best suited for use in any given application. Finally, several factors such as quality assurance requirements and cost should also be considered when making a decision about which flanged ball bearing is most suitable for an individuals needs.

Maintenance and Troubleshooting Tips for Flanged Ball Bearings

Flanged ball bearings are essential components for precise motion control, and their maintenance and troubleshooting is an important part of ensuring a successful project. To ensure optimal performance of flanged ball bearings, regular cleaning and lubrication should be done in order to keep them working efficiently.

If the bearing fails to perform correctly, it may need to be replaced entirely. Additionally, inspecting the mounting surface can help diagnose any misalignments or deformities that could affect its performance.

Troubleshooting tips for flanged ball bearings include checking the internal clearance before installation; if necessary it should be adjusted according to manufacturers recommendations. Also check for correct orientation when installing multiple flanged ball bearings as they must all turn in same direction towards each other when mounted together on a shaft or axle.

If you experience excessive vibration or noise during operation then inspect the preload settings as this could indicate improper assembly or incorrect alignment between two adjacent units. Finally, ensure proper lubrication levels are maintained at all times by regularly replacing oil seals and greasing moving parts with compatible lubricant products recommended by your bearing supplier’s technical department team.

Conclusion

In conclusion, Flanged Ball Bearings are a cornerstone of precise motion control and have been used in various industries for decades. Their efficiency and reliability make them ideal for many applications, from automotive to aerospace engineering. The range of sizes, materials, and styles available means there is a flanged ball bearing suitable for virtually any motion control requirement.

With their long-term durability and proven performance, these bearings are sure to remain an essential part of modern industry for years to come.